One of the main things that you can use your Dremel tool for is sanding down various surfaces. Here is the list of the most commonly used Dremel bits and their uses. However, I plan to cover a bunch of the more useful ones so that you can see just how handy a Dremel tool can end up being. There are quite a few, so I could never cover them all. In this guide, I plan to show you a large selection of the various Dremel tool bits out there. You just simply attach it to the front of your Dremel rotary tool and you are ready to go. What is a Dremel tool bit?Ī Dremel bit is a tool bit that can change the function of the Dremel rotary tool and allow it to do a variety of different jobs. But first, let me explain what exactly a Dremel bit is. I’m pretty familiar with the various tool bits that you can get for your Dremel tool, and so I figured that I would share that knowledge with you. However, to take advantage of this versatility, you have to find the right accessory or tool bit for your Dremel tool. The sheer amount of jobs that it can do is staggering. Much like its big brothers, the die grinder and angle grinder, the Dremel tool is an extremely versatile tool. They fit nicely in your hand and have a little spinning blade or a cutting tool known as Dremel bit at the end. Please be aware that mixing electricity and water can be very dangerous.Dremel tools are little rotary tools. If you do choose to drill near water or with attachments under water connected to your drill then you do so at your own risk.

Using rotary tools near water has never been, to the best of our knowledge, endorsed by any of the rotary tool manufacturers. If you're new to these drill bits then our Infographic 'How to Drill Through Glass' has easy to follow steps.ĭisclaimer. This will prevent the debris from being pushed up the core of the drill bit. To prevent this from happening, drill in and out (up and down) as you drill to dislodge the debris. Alternatively use a wire brush to clean out the core of the drill bit. If this happens it will often become dislodged when you begin drilling your next hole. We can't guarantee the precision with which you might achieve the perfect core but many have done so with success.įrom time to time the debris may become stuck in the core of the drill bit. Many of our customers use our core drill bits to achieve a core rather than to drill a hole.

#Dremel bits crack

Overheating can cause your material to crack or break and will shorten the life of the drill bit. The core allows drilling with water or a lubricant to swirl up inside the core whilst drilling, preventing overheating. Our diamond core drills are designed to drill holes in very hard materials and they do this by removing a cylinder of the material. You might also like to read our article: 12 Things you Should Know about Diamond Drill Bits There are also helpful hints on the correct speeds and pressure to be used.

#Dremel bits how to

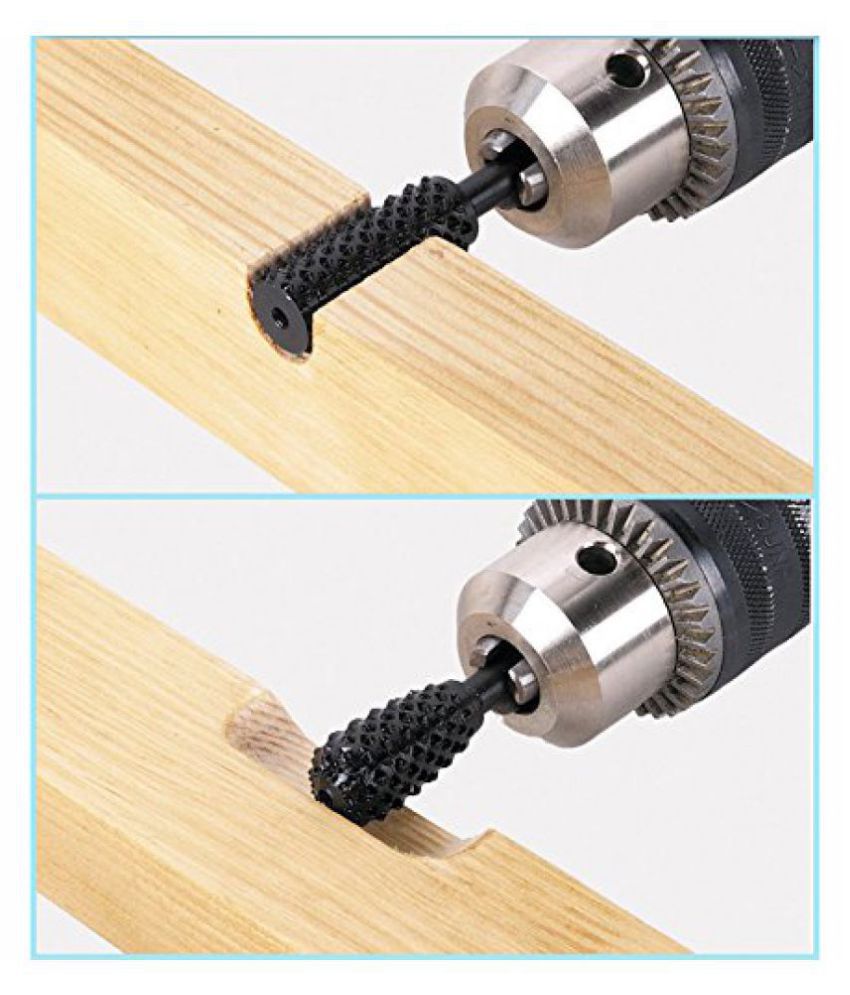

Here you will find tips and video footage on how to drill glass, how to drill gemstones, how to drill bottles, how to drill pebbles and how to drill sea glass. In order to get the best from our diamond tipped drill bits, please ensure you read through the Tutorials section on our blog before attempting to use our drills for the first time. Use at low pressure, let the drill do the work.Use with plenty of cold water (if drilling in a container, change the water when it turns cloudy).Tip: The following three crucial elements when drilling will prevent the diamond grit wearing off or burning away, will prevent the drill bit from snapping (too much pressure applied), prevent your material from cracking, and extend the life of your drill bits. This allows you to change drill bit sizes easily. If you have a Dremel rotary tool, we recommend the Dremel Multi Chuck. You will need an adjustable chuck or collet to hold these small diamond core drills, take a look under the 'Technical' tab below to find out the shank sizes of these drill bits. Users often keep a combination of both types in their tool kit, or you may find a personal preference to using one over the other. However, the small diamond coring drills have a smaller surface area of diamond grit and have a core running through them which makes them slightly less robust and not quite as durable as the small diamond drill bits. Small Diamond core drills will glide through material a little easier and more quickly than the solid ended small diamond drill bits making them the ideal choice for beginners. Small Diamond Core Drills Versus Small Diamond Drill Bits

0 kommentar(er)

0 kommentar(er)